Industrial Grease: Essential Lubrication for Machinery

Industrial grease plays a crucial role in the maintenance and efficiency of heavy-duty machinery and equipment. It is a semi-solid lubricant composed of a thickening agent dispersed in a base oil, often with additives to enhance performance. Unlike conventional lubricating oils, industrial greases provide superior adhesion, allowing them to stay in place even under extreme conditions.

Understanding Industrial Grease

Industrial greases are formulated to offer long-lasting protection, reducing wear and tear on machinery components. One of the key factors determining grease capability is the type of thickener used, which affects consistency and compatibility. The consistency of grease is measured using the National Lubricating Grease Institute (NLGI) Grades, where a higher number indicates a thicker grease.

Grease consists of petroleum-derived or synthetic oil combined with thickening agents such as lithium, calcium, or complex soaps. This unique formulation makes grease ideal for applications where continuous lubrication is not feasible, such as in bearings, gears, and high-friction environments. The primary function of industrial grease is to prevent metal-to-metal contact, acting as a sealant to protect equipment from contaminants and corrosion.

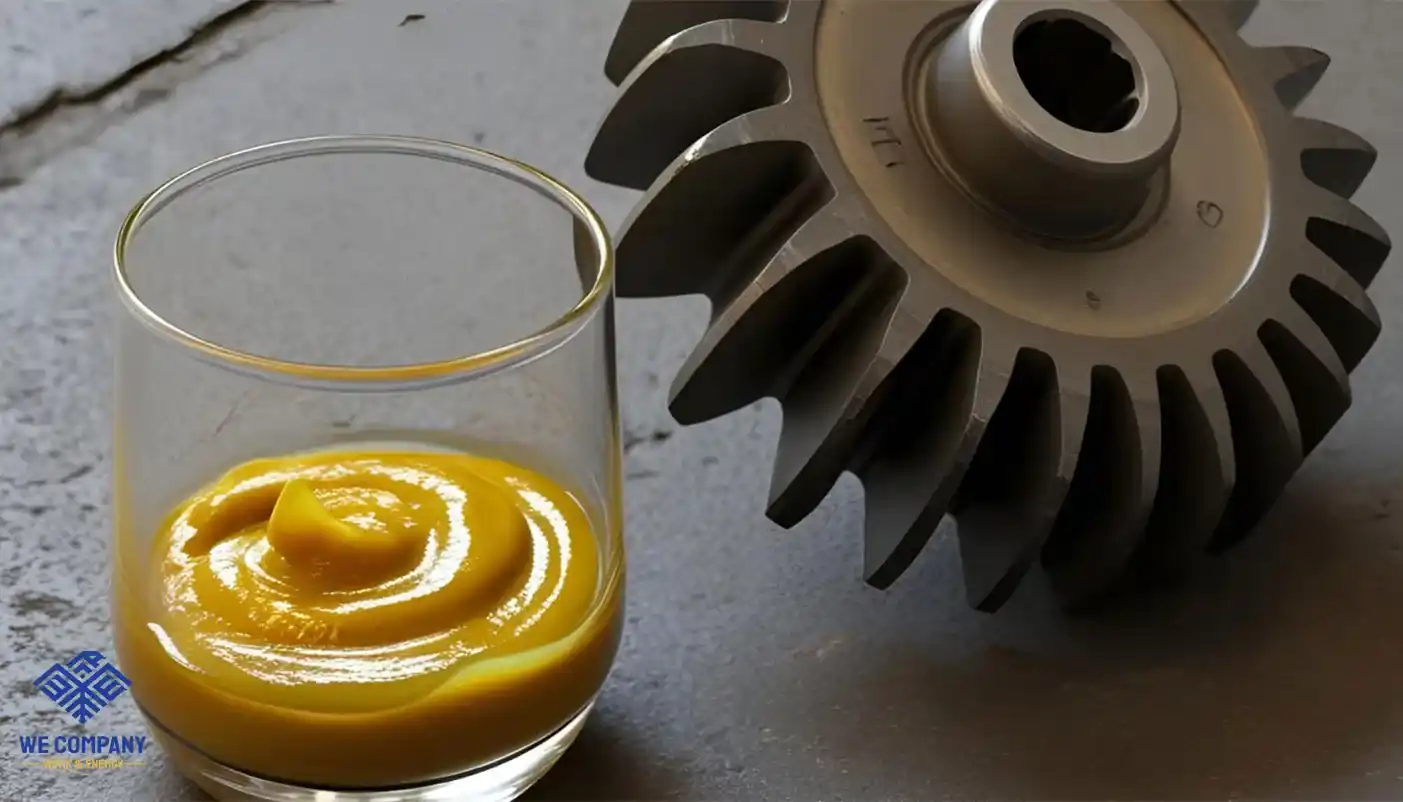

Calcium-Based Grease: Performance & Specifications

One of the most widely used greases in industrial applications is Calcium-Based Grease. This type of grease offers excellent water resistance, making it suitable for humid and wet environments. Below are its specifications:

Calcium-Based Grease Specifications

| Property | Unit | Test Result |

|---|---|---|

| Free Acid | %wt | 0.2 |

| Penetration (Unworked) | 1000 | D-1298 |

| Penetration (Worked) | 1000 | D-1298 |

| Dropping Point | °C | 102 |

| Flash Point | °C | 174 |

| NLGI Grade | – | 3 |

Key Benefits of Calcium-Based Grease:

- Superior water resistance and corrosion protection

- Good adhesion properties for long-lasting lubrication

- Ideal for use in high-moisture and marine environments

- Suitable for moderate temperature applications

Grease vs. Oil: Key Differences

While both grease and oil serve as lubricants, they differ in several key aspects:

- State at Room Temperature: Grease remains solid, whereas oil is liquid.

- Application: Grease is primarily used for machinery, while oil has a broader range of applications.

- Leak Prevention: Grease forms a better seal against contaminants compared to oil.

- Maintenance Costs: Grease-based lubrication systems tend to be more cost-effective due to reduced leakage and longer service life.

However, oil offers advantages in applications where draining and control over lubrication amounts are necessary, making it the preferred choice for certain industrial processes.

Lithium Grease: High-Performance Lubrication

Another widely used grease type is Lithium Grease, known for its excellent thermal stability and mechanical properties. This grease type is ideal for high-pressure applications and provides excellent resistance to water washout. Below are the specifications:

Lithium Grease Specifications

| Property | NLGI Grade | Unit | Test Method |

|---|---|---|---|

| Soap Type | EP | – | ASTM-D3340 |

| Dropping Point | Min 180 | °C | ASTM-D566 |

| Worked Penetration @25°C | 310-340 (Grade 1), 265-295 (Grade 2) | Mm/10 | ASTM-D217 |

| Mineral Oil Viscosity @40°C | Min 160 | CSt | ASTM-D445 |

| Mineral Oil Viscosity @100°C | Min 15 | CSt | ASTM-D445 |

| Water Wash-Out Resistance | Max 10 (Grade 1), Max 5 (Grade 2) | Mass% | ASTM-D1264 |

| Copper Strip Corrosion | 1b | – | ASTM-D4048 |

| Oil Separation (18 hours @40°C) | Max 5 | – | ASTM-D1742 |

| Operating Temperature Range | 20-120 | °C | – |

| Color | Yellow | – | – |

Key Benefits of Lithium Grease:

- Excellent resistance to high temperatures

- High load-bearing capacity for industrial applications

- Superior mechanical stability for extended service life

- Outstanding water resistance, preventing washout in wet conditions

Choosing the Right Industrial Grease

Selecting the appropriate grease depends on various factors such as operating temperature, load requirements, and exposure to moisture or contaminants. Calcium-Based Grease is ideal for high-moisture environments, while Lithium Grease is preferred for high-temperature and heavy-load applications.

For industries requiring high-performance lubrication, using the right grease ensures smooth operation, reduced maintenance costs, and extended machinery lifespan. To learn more about our range of industrial greases, contact us today!

Suggested content:

Calcium-Based Grease

Lithium Grease

Contact Us

Need help selecting the right base oil or want to request a quote? We’re here to assist you.

WhatsApp: (+971) 585992028

Phone: (+971) 58 599 20 28

Email: info@workandenergy.com

Office Address: No. 106, Sabkha Tower, Deira, Dubai, UAE

No comment